Overview

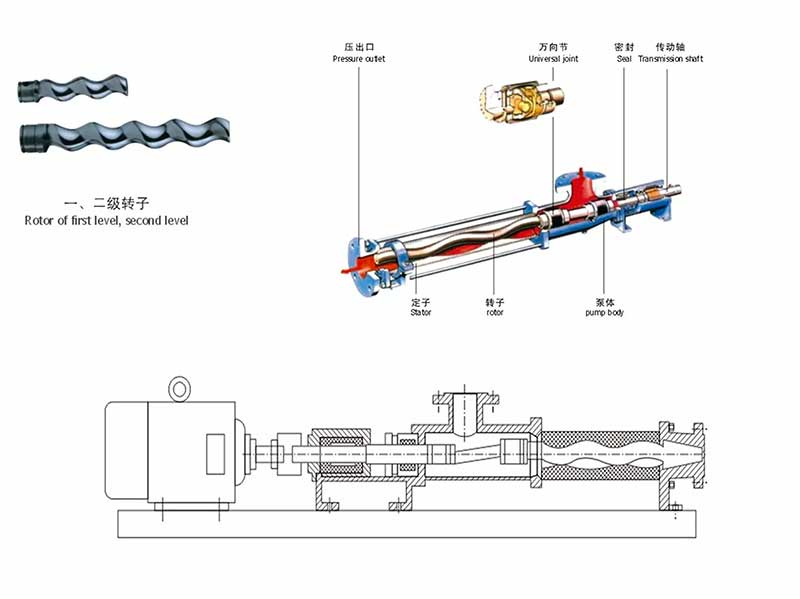

The Sanitary screw pump is a special kind of positive displacement pump. Its main working parts are a screw (called a rotor) in the shape of an eccentric helix and a screw bush (called a stator) with a double helical inner surface.

When the motor drives the pump shaft to rotate, the screw rotates around its axis on the one hand, and on the other hand, it rolls along the inner surface of the bushing, thus forming the sealed chamber of the pump. The liquid in the sealing cavity advances one pitch for each revolution of the screw. With the continuous rotation of the screw, the juice is pressed from one sealing chamber to the other in a spiral shape and finally squeezed out of the pump body.

The high-viscosity sanitary stainless steel single screw pump is a new type of liquid conveying machinery. It has the advantages of simple structure, safe and reliable operation, convenient use and maintenance, continuous and uniform liquid discharge, and stable pressure.

Advantage

- Low inertial force of the rotating parts, ideal for very high speeds

- Less sensitive to incoming gas and dirt than other rotary pumps;

- Uniform and continuous flow, slight vibration, and low noise;

- No end-flow pulsation and pulsation; Smooth operation and stable flow rate.

- Fluid can be conveyed in forward and reverse directions.

- The ability for multi-phase mixed transportation of liquid, gas, and solid;

- Good suction performance and self-priming ability;

- Solid structure, easy installation, and maintenance.

- Sanitary design with a flash protection cover.

- The spiral sealing line completely separates the suction cavity and the discharge cavity so that the pump has the same isolation function as a valve;

Application

The sanitary screw pump is suitable for food, textile, paper, petroleum, chemical, shipbuilding, construction, nuclear, metallurgy, mining, sewage treatment plants, power plants, etc.

Parameters

| Product Name: | High-viscosity sanitary stainless steel single screw pump |

| Material: | SS304/SS316L/1.4301/1.4404 |

| Seal Material: | EPDM (Standard) |

| Max. Flow: | 60m3/h |

| Max.Pressure: | 0.6Mpa |

| Max. working temperature: | 150 C / 302 F |

| Max. rev: | 960 rmp |

| Self-priming height: | 6m above |

| Allow the grain diameter: | 150mm |

| Mechanical seal: | SIC/SiC/EPDM(Standard) |

| Motor power: | 0.55kw-15kw |

| Sealing option: | Sanitary single mechanical seal/Double mechanical seal with the cooling system |

| Voltage: | 220V, 240V,380V,440V |

| Motor: | ABB, 50hz/ 60hz |

| Surface treatment: | Inner polished and Sandblast outside |

| Available connection: | Clamp, Thread Butt weld, Flange |

| Available standard: | DIN, SMS, 3A, RJT, ISO/IDF |

| Application: |

Dairy and food industry, honey, chocolate, jam with high viscosity |