Paper & Pulp

Pumping applications of progressive cavity pumps in the paper and pulp industry.

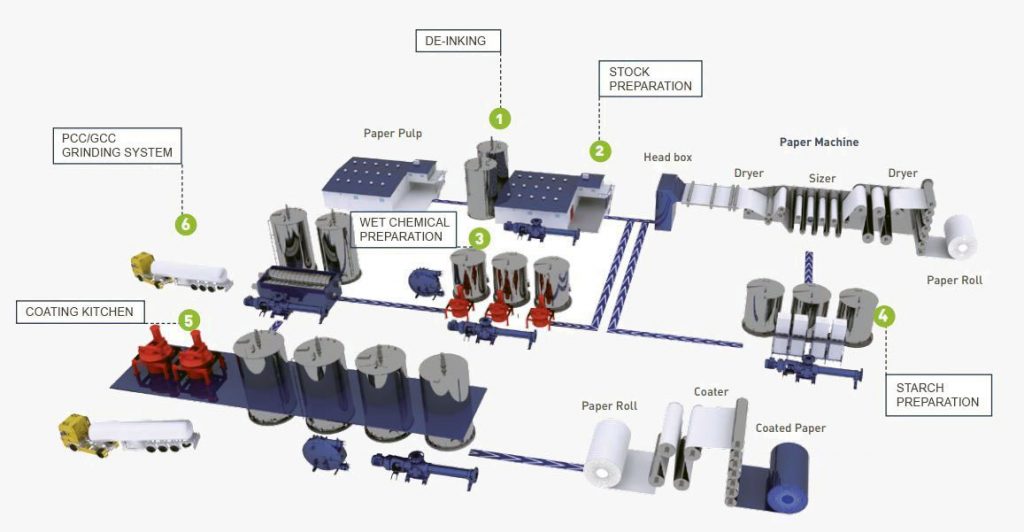

Common Pump Applications

The papermaking process involves metering, mixing and pumping a wide variety of chemicals and high temperature, abrasive material. Our Screw Pump can handle these caustic chemicals and will pump abrasives without damaging or wearing out the pump. Conventional diaphragm metering pumps often pump in short pulses which over time can cause damage to the mills piping systems.

Applications:

- Wood Chipping / Debarking

- De-inking Chemicals

- Wet End Chemical Preparation

- Starch Preparation

- Coating Color Kitchen

- Wastewater and Sludge Dewatering

- Stock Preparation

Application scenarios

Filtration of Chemical Process Ingredients

The screw pump is mainly used to transport chemical substances, such as lye (NaOH, Na2S, etc.) for cooking and black liquor and white mud produced by alkali recovery; bleaching liquid chlorine Cl2, chlorine dioxide ClO2, hydrogen peroxide H2O2, water glass Na2SiO3, Liquid transportation such as chelating agent EDTA, concentrated sulfuric acid H2SO4, caustic soda NaOH, etc.; talc pulp, glazing resin, dye, latex, etc. for papermaking; flocculant transportation for wastewater treatment and treated sludge, sewage, etc.; medium and high concentration bleaching technology, conveying medium and high concentration pulp, etc.

Need Help Selecting a Pump?

For help selecting the most efficient pump for your project, send an E-mail to sales@hw-screwpump.com.